The Australian print industry and Europe are, naturally, quite different. From the way they approach the business of print through to the elements of production they prioritise.

In this blog, we discuss the main differences we identified on a recent trip to visit trade printing facilities in Europe.

European Printers Prioritise Quality

The European print market seems to value print quality over speed and volume. This is due to the expectations and diversity of customers in this market. Therefore the throughput is generally lower and print modes set finer to achieve those small percentage gains in resolution. This is evident in the way that European printers invest in equipment that offers more control over quality optimisations than throughput. Additionally, the European market is home to many high-end print shops that specialise in luxury and bespoke prints at volume – albeit with much slower turnaround.

That’s not to say that resolution in large-format printing in Australia is significantly worse. We’re talking minimal differences in quality – it’s just that Australian resellers prioritise volume.

Sustainability Efforts Are More Mature than Australian Print Industry

Another major difference between the European and Australian print markets is the emphasis on sustainability. There is a greater emphasis on using environmentally friendly materials and reducing energy consumption in print. Not only is less concern about costs associated with sustainability.

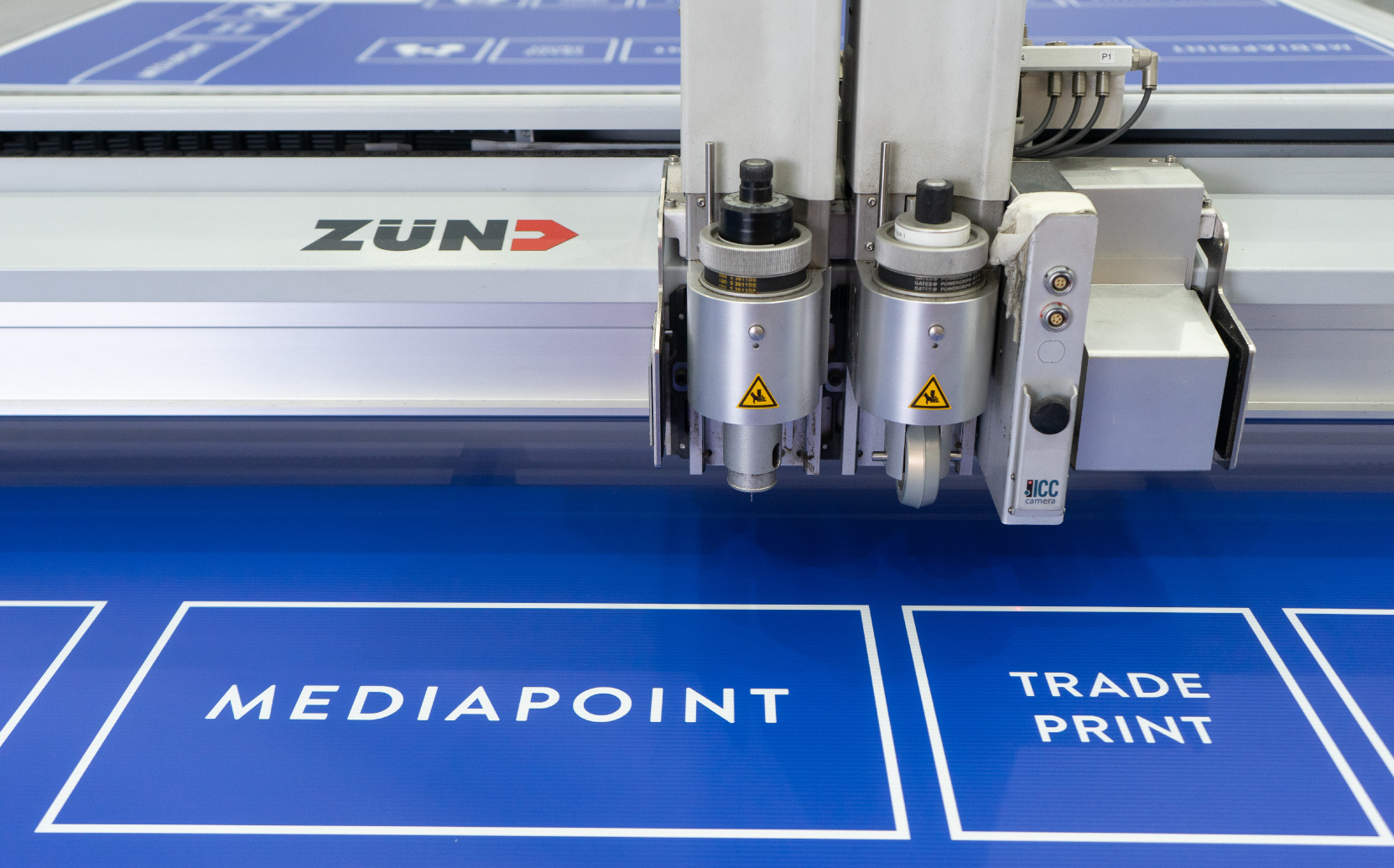

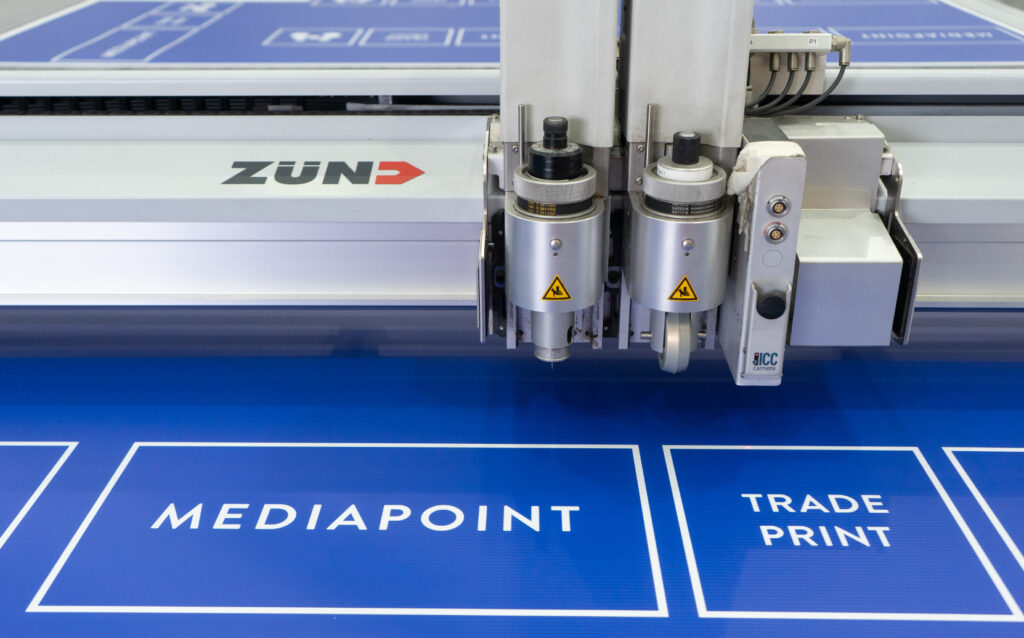

Greater (and more regular) Investments in New Equipment in Europe: In Europe, printers tend to make greater and more regular investments in new equipment. This is because the European market is more competitive and printers must stay ahead of the curve to remain competitive. Additionally, European printers also tend to invest in new equipment to ensure that they can produce prints of the highest quality.

Staff turnover is much lower in Europe and staff stay with companies – buying into the vision and mission of businesses: Finally, the European print industry is known for having a lower staff turnover rate compared to the Australian print industry. Staff in Europe tend to stay with companies for longer periods of time, and they tend to buy into the vision and mission of the business. This is because the European market is more mature and stable, and staff are more likely to find job security and stability in the European print industry.