Learn about our brand new label and sticker printing solution that’s changing the game for Australian printers.

We first embarked into the label and sticker printing market 12 years ago. So we’re all too familiar with the challenges of the medium. Over time, and still until recently, we’ve encountered the same obstacles and pain points our customers (and peers) faced.

Most notably was a forced reliance on wide-format printers, plotters, and manual cutting tools to produce jobs. It can be a painstaking process, particularly for smaller, high-quality projects.

But despite the inefficiency and quality not meeting our idea standards, it had remained the most cost-effective solution. Many other trade printers and traditional print shops still operate this way. But for Mediapoint (and our print resellers and brokers) things are finally changing…

The Ideal Label and Sticker Printing Solution

We never stopped looking for better technology throughout our journey. We believe in doing things right and investing in the best to ensure we never outgrow our capabilities. So since discovering the equipment that would integrate with, and enhance, our streamlined processes we’ve been meticulously working on a keystone project.

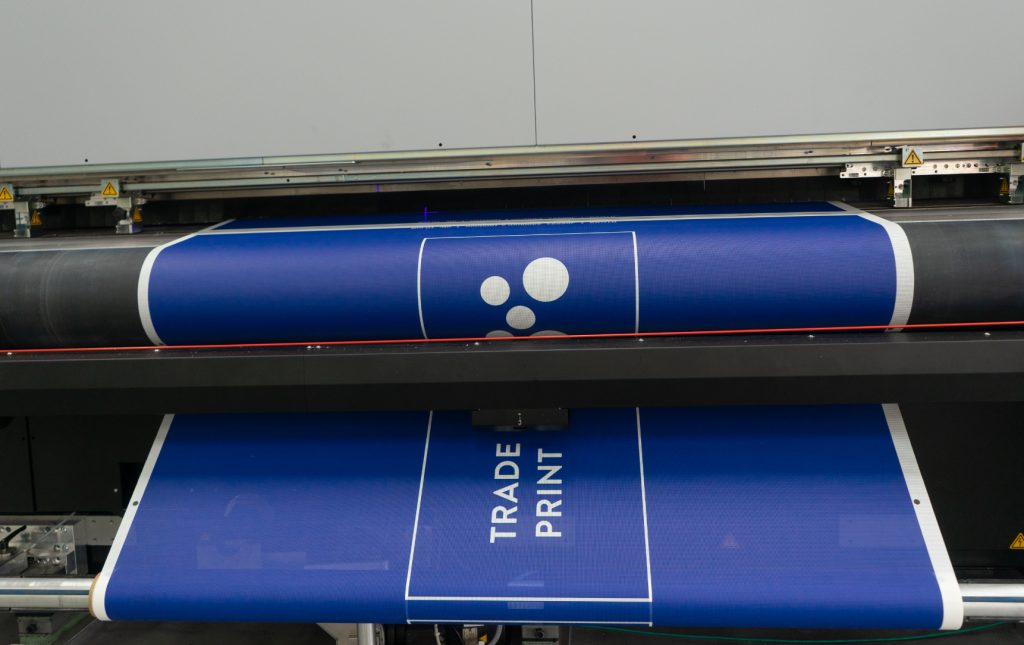

After two years, we believe we have commissioned the best solution in Australia. We excited to announce the addition of a Durst Tau 330 RSC E to our equipment lineup. It sets the standard for label printing – offerring unparalleled quality and efficiency.

What’s So Good About This Printer

It’s not just hyperbole – the Tau 330 RSC E offers some compelling benefits. Here’s why we’ve invested in this label and sticker printer…

Unparalleled Label and Sticker Quality

The Tau 330 RSC E prints at 1200dpi with a 2 picoliter drop and minimal dot gain. That makes is the highest quality inkjet printer on the market. Print elements are crisp and clean even at both macro and micro scale. The print clarity remains whether you need a label up to 1m in length, or QR codes, barcodes, and text at 5mm and under.

Plus, the Tau matches the throughput of our other machines meaning there’s no compromise between speed and quality.

Outdoor Durability

The outdoor-durable ink used by this machine eliminates the need for lamination. Yet stickers and labels can withstand outdoor conditions for up to two years. This unlocks a wide range of applications in combination with custom size options, a large die library, and the aforementioned print quality.

Trust & Reliability

We’ve partnered with Durst Group for a number of years and feature many of their machines in our processes. Their reputation for reliability is well-known, and the proof is in the jobs (stickers or otherwise) that we produce everyday.

The Tau 330 RSC E is no exception. It offers consistent throughput and fits in seamlessly with our streamlined processes. This makes great savings in a number of areas without forsaking quality on labels and stickers. This means we can continue to pass savings onto our resellers, offering them more margin to play with.

Future-Proofed Label and Sticker Printing

Our new Durst printer also has the potential to utilise White UV Ink in the future. Plus, our tight-knit relationship with the manufacturer makes it likely that we’ll have first access to upgrades and optimisations.

That will enable us to offer unique applications and expand services to Australian print resellers as the market (and demand) grows.

What Does This Mean for Our Customers

We’re obviously excited about this new addition to our service offerings – and you should be too. With the Tau 330 RSC E Mediapoint trade customers get:

- Free blind shipping as standard

- A best-in-class label solution that doesn’t require laminate.

- Australia’s largest die library – order custom sizes and custom shapes.

- Low minimum starting prices on sheets and rolls at any order volume.

- Application-ready labels and stickers – no white edges!

- A 100% easy peel guarantee. Never worry about labels being cut too deep.

- The ability to order labels up to 1m long.

- Instant pricing and industry-leading, 2-day turnaround times.

We’re absolutely redefining what’s possible when it comes to labels and stickers for Australian print resellers. If you’re interested – put us to the test!

Make sure your are registered for a trade account to make the quantum leap today.